You’ve probably noticed that fluids don’t flow through pipes and equipment without paying a price. That price is a pressure drop, and if you’re not paying attention to it, you’re likely wasting energy and money.

Let me walk you through what really matters.

What Pressure Drop Actually Means

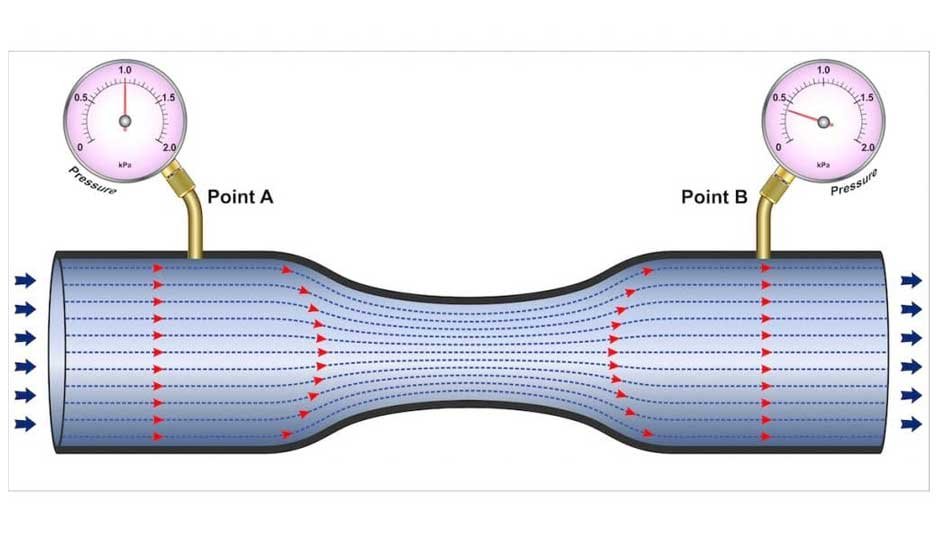

So, how does pressure drop affect processing systems? Well, when fluid moves through your system—whether it’s water, oil, gas, or anything else—it loses pressure along the way. Think of it like friction eating away at the energy you’ve put into moving that fluid. Every elbow, valve, length of pipe, and piece of equipment creates resistance. And resistance means pressure drop.

The bigger the drop, the harder your pumps or compressors have to work. It’s as simple as that.

Why You Should Care

Here’s the thing: pressure drop directly impacts your operating costs. When you lose pressure, you need more energy to maintain flow. More energy means:

- Higher electricity bills

- Oversized pumps and motors

- Increased maintenance from equipment working too hard

- Potential production bottlenecks

I’ve seen facilities reduce their energy consumption by 20-30% just by optimizing pressure drop. That’s real money.

The Main Culprits in Your System

Pipe friction is the obvious one. Longer pipes and smaller diameters create more resistance. But you already knew that.

What catches people off guard are the fittings. Those 90-degree elbows you casually threw into your design? Each one creates a localized pressure loss that adds up fast. Valves do the same thing. Even when they’re fully open.

Flow velocity matters more than most people think. Double your velocity, and you roughly quadruple your pressure drop. The relationship isn’t linear—it’s exponential. So when you’re tempted to downsize that pipe to save on capital costs, think twice.

Then there’s equipment like heat exchangers, filters, and reactors. These are necessary pressure drop sources, but you can optimize them.

Getting the Balance Right

You’re always making tradeoffs. Bigger pipes mean less pressure drop but higher upfront costs. Straighter runs are better for pressure, but your plot plan might not allow it.

The key is understanding where your pressure drop budget matters most. Not all systems are equal. In a low-pressure application, losing 2 psi might be catastrophic. In a high-pressure system, it might be negligible.

Practical Steps You Can Take Today

Run the numbers first. Don’t guess. Use proper calculations or software to model your system. The Darcy-Weisbach equation is your friend for pipe flow. For fittings and valves, you’ll need K-factors or equivalent lengths.

Look at your velocity. If you’re running above 10 ft/s for liquids or creating noise in gas lines, you’re probably pushing too hard.

Consider your piping layout. Sometimes adding a few feet of pipe to eliminate an elbow pays for itself quickly. Long-radius elbows are better than short-radius. Gradual transitions beat sudden contractions.

Don’t forget about your filters. A clogged filter is a pressure drop nightmare. Monitor those differential pressures and change elements before they choke your system.

When Pressure Drop Becomes Critical

You’ll know you have a problem when pumps cavitate, flows decrease, or equipment can’t meet spec. By then, you’re in reactive mode.

Better to be proactive. Set up pressure monitoring at key points. Watch for trends. A gradually increasing pressure drop often signals fouling, scaling, or other maintenance issues before they become emergencies.

In batch processes, pressure drop can affect residence time and mixing. In continuous processes, it impacts throughput. You need to know your system’s sensitivity.

The Bottom Line

Pressure drop isn’t just an engineering calculation you do once during design. It’s an ongoing operational reality that affects your efficiency every single day.

Minimize it where practical. Monitor it constantly. And remember that every psi you save is energy you don’t have to pay for.