In 2025, the food manufacturing industry continues to evolve at a rapid pace, driven by changing consumer preferences, stringent regulatory requirements, and the need for improved efficiency.

With increasing pressure to maintain quality, traceability, and operational effectiveness, food manufacturers must leverage technology to stay competitive. One of the most effective solutions is implementing an Enterprise Resource Planning (ERP) system. Below, we explore why you should invest in Food Manufacturing ERP Software this year.

Enhanced Food Safety and Compliance

Food safety regulations are becoming stricter worldwide, with compliance frameworks like HACCP, FSMA, and GFSI demanding rigorous tracking and reporting. An ERP system helps food manufacturers adhere to these regulations by automating data capture, ensuring proper documentation, and providing real-time traceability. This reduces the risk of non-compliance penalties and enhances consumer confidence in the brand.

Improved Traceability and Recall Management

In an industry where recalls can be costly and damaging to reputation, having a robust traceability system is crucial. An ERP system allows manufacturers to track raw materials from suppliers through production to distribution. In the event of a recall, manufacturers can quickly identify affected batches, minimizing disruption and ensuring swift corrective action.

Optimized Inventory and Supply Chain Management

Balancing inventory levels is a common challenge for food manufacturers. Overstocking leads to waste, while understocking can cause production delays. An ERP system integrates real-time inventory management, demand forecasting, and supplier coordination, helping manufacturers maintain optimal stock levels, reduce waste, and ensure timely deliveries.

Increased Production Efficiency

Manual and fragmented production processes lead to inefficiencies and higher operational costs. ERP systems streamline production scheduling, monitor equipment performance, and automate quality checks, leading to increased productivity. By optimizing resource utilization, manufacturers can meet customer demands more effectively while reducing costs.

Better Financial Management and Cost Control

Profit margins in food manufacturing can be tight, making financial visibility critical. ERP systems provide detailed insights into cost structures, pricing strategies, and profit margins. With accurate real-time financial data, manufacturers can make informed decisions, control costs, and enhance profitability.

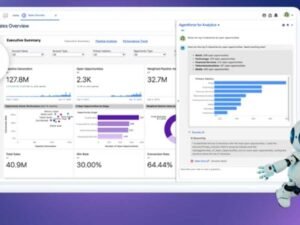

Real-Time Data and Business Intelligence

In a fast-moving industry, timely decision-making is crucial. ERP systems consolidate data from multiple departments into a single dashboard, offering real-time insights into sales, production, inventory, and finances. Advanced analytics and reporting tools enable manufacturers to identify trends, optimize operations, and enhance strategic planning.

Scalability and Future-Proofing

As food manufacturers grow, their operational complexity increases. A scalable ERP system accommodates business expansion, whether it involves adding new product lines, expanding to new markets, or integrating emerging technologies like AI and IoT. Investing in an ERP system now ensures long-term adaptability and competitiveness.

Final Thoughts

In 2025, food manufacturers cannot afford to rely on outdated, manual processes. An ERP system is no longer a luxury but a necessity to maintain regulatory compliance, improve efficiency, and drive profitability. By implementing an ERP solution, food manufacturers can position themselves for sustained success in an increasingly demanding market.

If you’re a food manufacturer looking to enhance operations, now is the time to explore ERP solutions tailored to your industry’s needs.